Rollover Semi

Yesterday, about

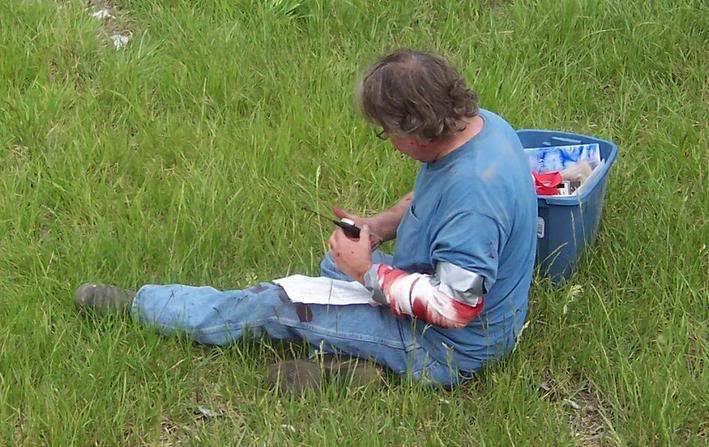

This is the driver- he refused to go to the hospital, that arm, looks bad!

All-in-all, they did a good job! For those of you following my previous posts on Bloomingdales recoveries, you will note that my biggest beef with them in my previous posts was the lack of safety vests. You will note that all but 2 people had some sort of reflective gear on!!! (And on of the 2 people had some bright yellow on) so they are getting it! Brue said to me as we were leaving, that he �learns something new every time he works a recovery.� This is great and it is exactly the attitude to have. Everyone should have that attitude. And that is the reason behind my taking photos and posting them- so myself and someone else might learn something.

You will note that they chained all the axels to the frames. (The ones they pulled from)

As some of you know, I don�t like pulling from the axels without having some straps on the trailer. But it is not loaded and so it is not a big deal.

The catch vehicle. This is a tricky problem because they can not put a vehicle in the rear of the trailer. As you may be able to see, they opted to use the rotator (again!!!) as the catch vehicle. They opted to have the winch line tighten as the truck came over and then lower it to the ground. 2 things- one- (not in this case but for learning purposes) when using this technique, is EXTREEMLY important not to shock load the catch line!!!!!!!!! If you do not perform this maneuver correctly, you will screw up your rotator not to mention, possibly roll it over!!!!! They did a good job, a tiny bit of a shock but not bad. 2nd thing is you have to be careful to have the boom far enough away from where the trailer will end up so they don�t hit. AGAIN- that did NOT happen here but just a tip for learning purposes.

You may also notice that they recovery truck operators stood somewhat behind the trucks except the rotator operator. This is great and very safe for them but very dangerous for the rotator operator. Although it is important to see what is going on, if something goes flying when that truck comes over, it should seriously injure or kill someone! It is for this reason; I strongly recommend that everyone on scene wear safety glasses, hard hats, and steel toed boots. And remember, if YOU are doing the recovery, you are in charge!!! If something goes wrong (God forbid), who do you thing the first name will be on the lawsuit- YOU. If someone is not in proper gear (including cops, firemen, press, other drivers, ect�.) it is your responsibility to have them move back a safe distance or dawn proper gear. \

Getting back to the position of the recovery personnel. I like to follow the Wreckmaster way of doing recoveries. 1 person operates each tow truck and 1 supervisor watching everything and directing all operators. One other person as the look out for the other side of the truck as well as the lesson between the supervisor and the control vehicle operator.

You will also note that they removed the driveshaft b4 the upright and they did a quick walk around inspection b4 the upright- this is great!!! But they did not cage the brakes on the tractor b4 the upright (they did some caging after the upright on the drivers side) and they did not use wood to caulk the wheels during upright. But I do not want to harp on that because they did a good job!! Keep it up!!

i almost forgot, i want to give credit to the opperators that worked this recovery. Chris, Breu, Mike, Tim,

Todd from Bost Dumping, and Matt from Diamond Truck repair. Great Job guys!

0 Comments:

Post a Comment

<< Home